What is cold extrusion?

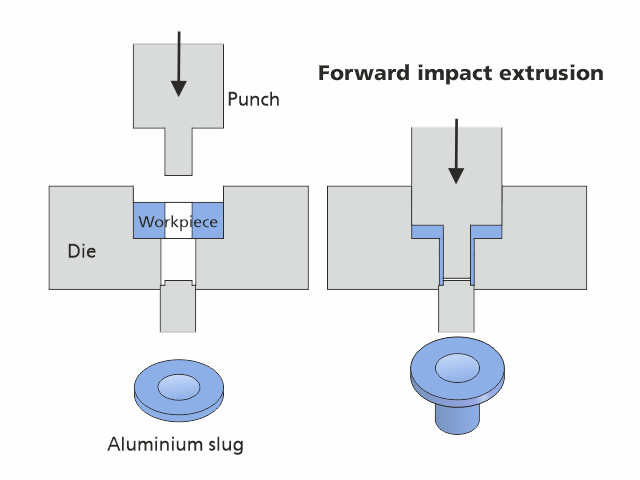

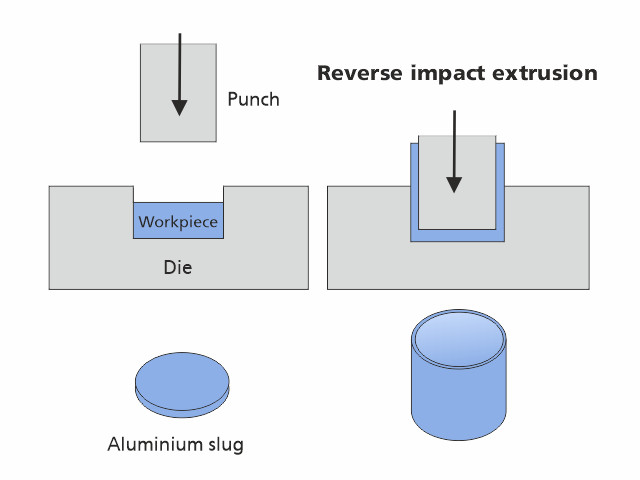

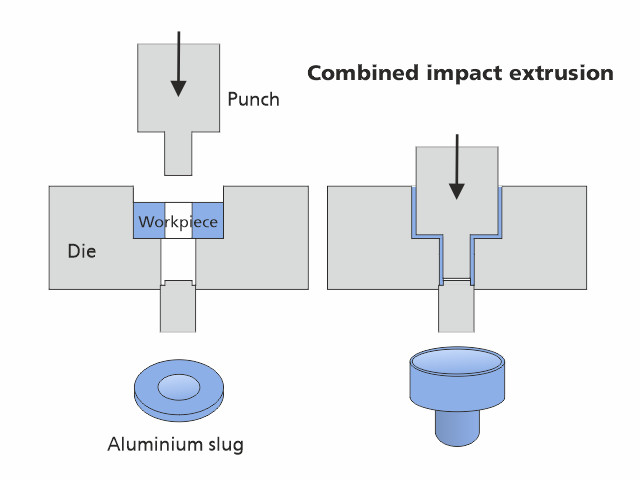

Aluminum blanks (slugs) are placed in a die at room temperature and pressed with a press punch under high pressure in the die. The material immediately begins to flow and adapts to the die and the press plunger in a precise manner. This produces precise workpieces with a high surface quality.

Depending on the direction of flow of the material, a distinction is made between forward, reverse, transverse and combined impact extrusion. Component lengths of 10 times the diameter can be pressed in one stroke (e.g. D 25 mm → maximum component length of 250 mm). The cold extrusion technique can be used to produce round, square, rectangular and special shapes. The parts should be built as symmetrically as possible.

Advantages of the impact extrusion process

- Low tooling costs

- Low component costs

- Optimal raw material yield

- Pressing to finished size of functional surfaces and geometries

- Increased material strength due to cold forming

- Tight (no blowholes)

- No surface scaling

- Repeated accuracy (process reliability)

- High output

- Individual product design: unique selling point