In most cases, impact extrusion blanks have material overflow and machining allowances that must be subsequently removed mechanically. Typical follow-up operations are:

- Re-hammering

- Trimming

- Punching

- Bending

- Einziehen

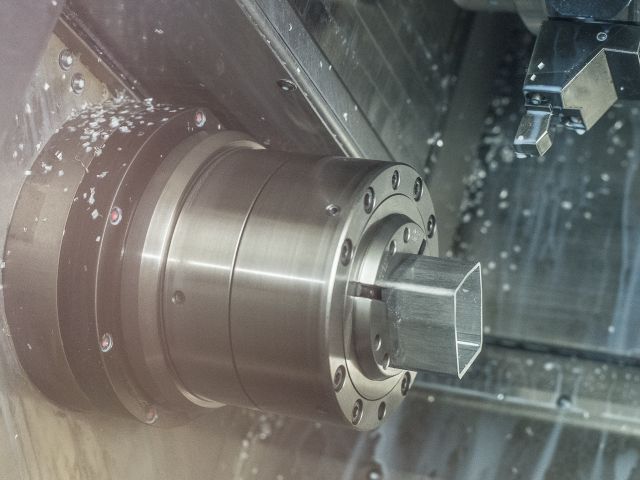

- CNC-machining (turning, milling, drilling)

- Thread forming/ thread cutting

- Surface treatment

(blasting, brushing, anodizing, chromating, powder coating)

COLDEX AG offers all these finishing processes and thus ready-to-install components.